Project description

Geurts supplies a complete thermal oil system for a thermal cleaning plant. Our client cleans contamined mineral waste products that can only be decontaminated by way of thermal desorption.

The thermal cleaning unit can clean sandy contaminated soil, clayey soil, peaty soil, sandy soil, tar-containing asphalt, mercury gravel, cyanide soil, oil-bearing soil, PCB-containing soil, tar mastic and roofing felt.

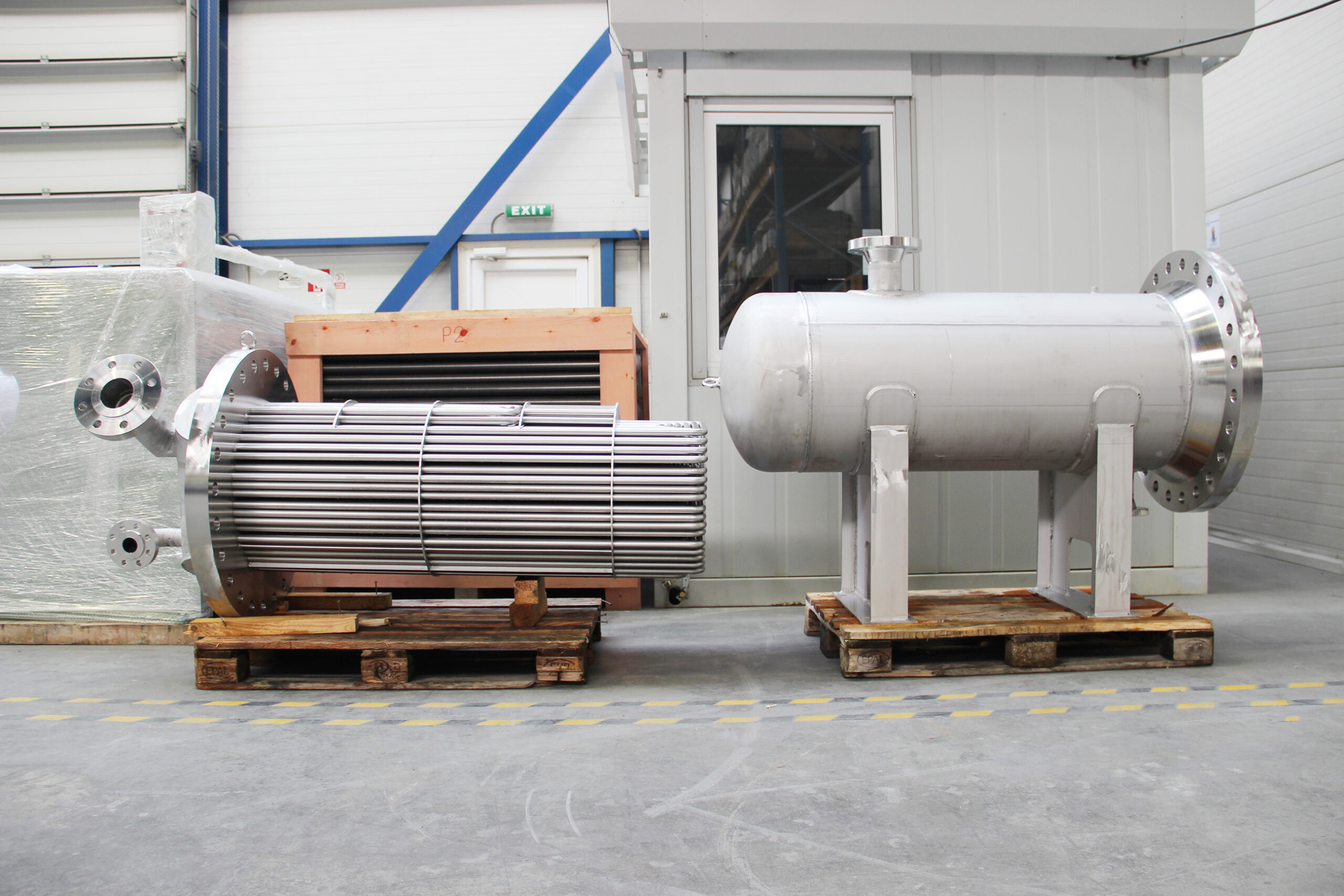

Geurts received the order to supply a total processing system including seven (7) system air coolers, eleven (11) heat exchanger bundles, thermal oil pumping and monitoring systems, required steel structures and the entire electrical system for power and control.

Some features of this project:

• Eleven (11) stainless steel heat exchangers, made of Ø114,3 mm (4 inch) tubes, in total over 9.000 meter and a weight of almost nineteen (19) metric ton each.

• Seven (7) steel frames including each three (3) fan drives Ø 2155 mm (Ø 7Ft) and heat exchanger bundles for cooling.

• Two (2) thermal oil pump systems including circulation pumps, valves and expansion tanks fully assembled on skid frames.

• All connection piping in between all elements for the thermal oil cycle.

• Steel structures for support of all equipment

• Electrical engineering and installation for process control and power

• Engineering, manufacturing, assembly, transport, installation on site, commissioning, hand-over

• Group performance by several deliveries of Heilig Group members

Dutch

Dutch German

German French

French