Swinkels Family Brewers

Economizers & flue gas condensers

In 2020, after an extensive study, a major energy-saving project was realized at Swinkels Family Brewers, the brewery known for Bavaria beer, among other things.

Marthijn Jungeburth (Manager Sustainability, Safety & Environment): “Circular business means not letting raw materials, energy and materials go to waste and making sure they retain their value.”

The goal: 15-20% energy savings

How? Higher residual heat efficiency + lower energy consumption and CO2 emissions

In addition to reducing CO2 emissions, this also results in a two-fold cost reduction. Firstly, by reducing gas consumption and secondly, there is a substantial saving on the much-discussed CO2 emissions tax.

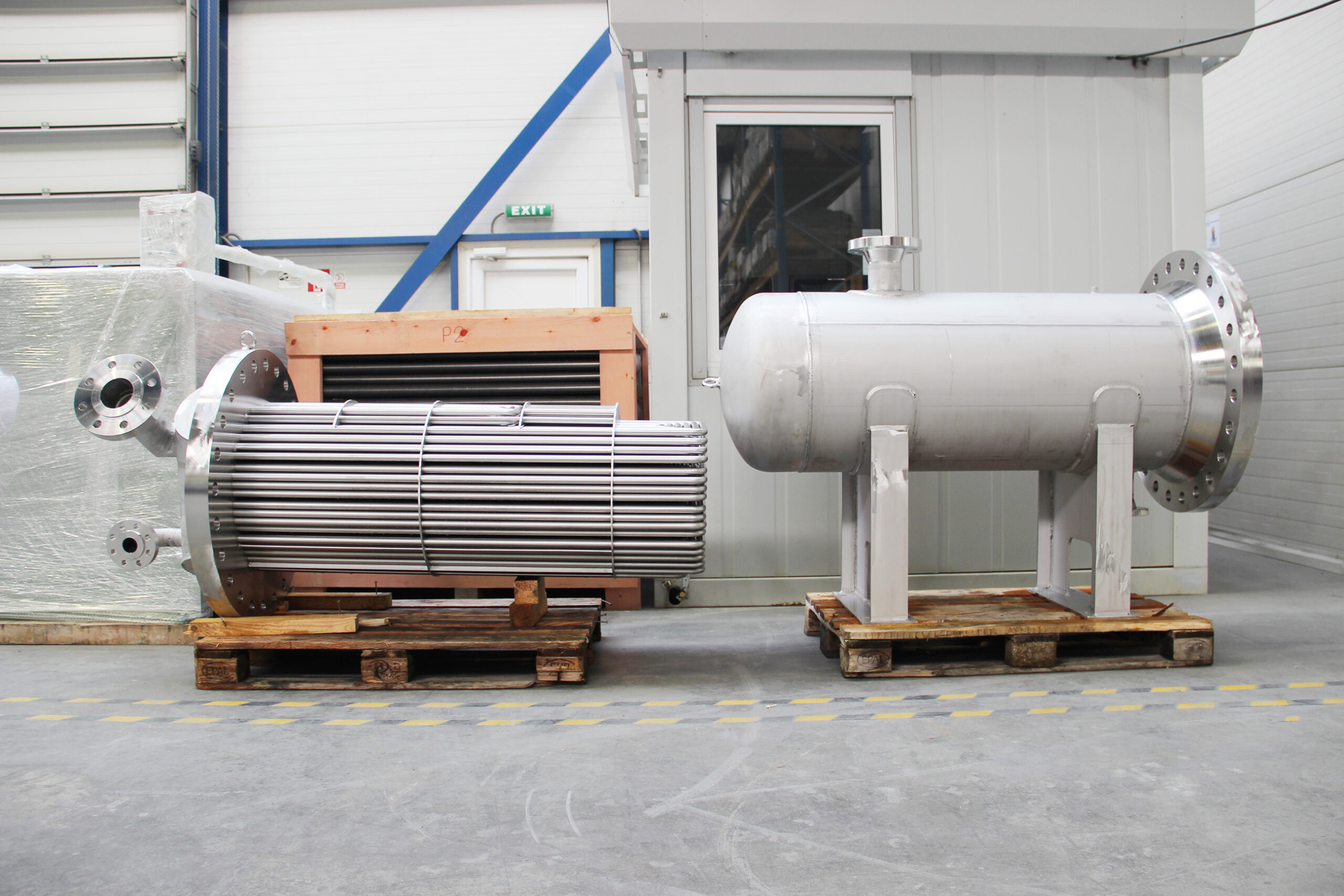

The project consists of liquid/gas heat exchangers (economizers and flue gas condensers) recovering the waste heat from the exhaust gas of the boiler plant (incl. 6MW gas turbine) and leaving the flue gas at a temperature of ~40°C.

The chosen solutions with economizers and flue gas condensers show the enormous potential of waste heat utilization in boiler plants, where almost all waste heat is recovered from the flue gas.

Results:

– Saving of 4 million m3 of gas per year

– 7.000 ton Co2 reduced per year

– Total saving of 0.7 million euros per year

Project highlights:

Country: Netherlands

Client: Swinkels Family Brewers

Application: Liquid/gas heat exchanger

DO YOU WANT TO KNOW MORE?

Sales team:

E: info@geurtsbv.com

T: +31 (0) 88 1704 600

Know what you want? Fill out our contact form:

Dutch

Dutch German

German French

French