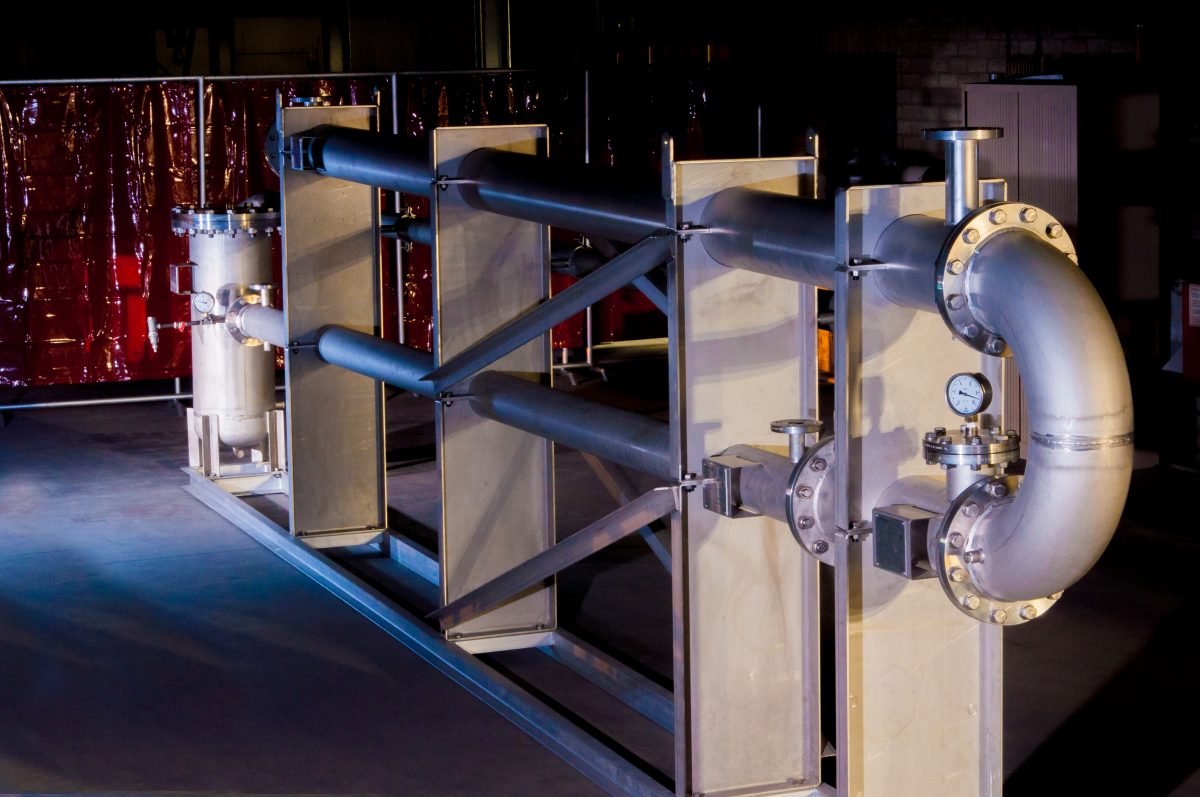

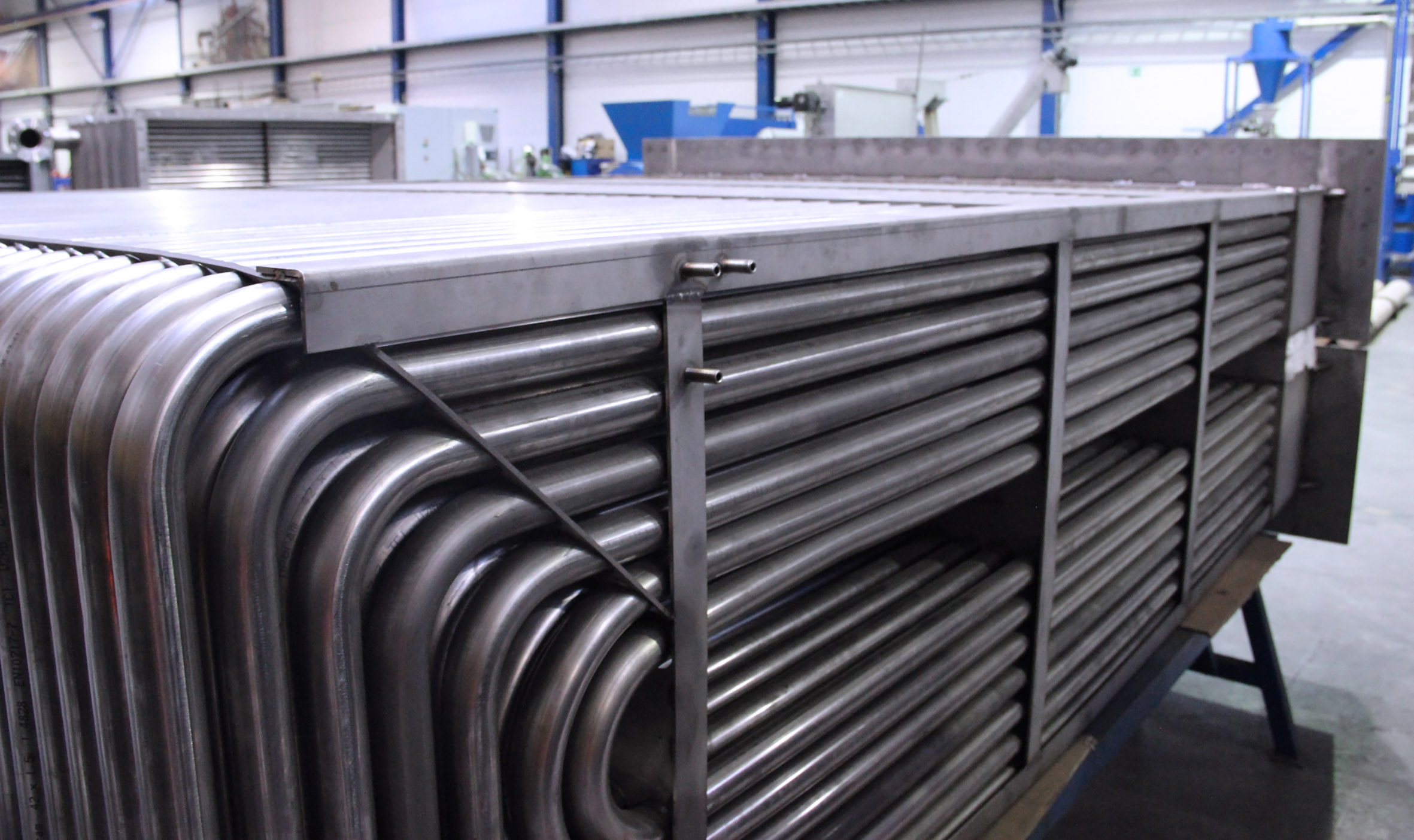

ENGINEERING PRODUCTS FOR HEAT EXCHANGE AND WASTE HEAT RECOVERY

Where once many industries felt the pressure of operating efficiently and economically, nowadays reducing the carbon footprint is an additional factor that can no longer be evaded. This calls for innovative engineering of complete production processes, installations, and equipment for existing customers and new markets.

TAILOR-MADE SOLUTIONS

Geurts supplies a complete range of heat exchangers and waste heat recovery products to regenerate waste heat and to recycle energy from various production processes into renewable energy. Our experienced engineers design tailor-made solutions including high pressure equipment (PED), extremely high fluid temperatures (liquids and gases) or dangerous substances that require complex and specialized applications.

From our in-house manufacturing facility, we offer a total solution; from heat transfer calculations and engineering designs to the production of your specific air preheater or heat exchanger. A single contact for your comprehensive solution.

Dutch

Dutch German

German French

French