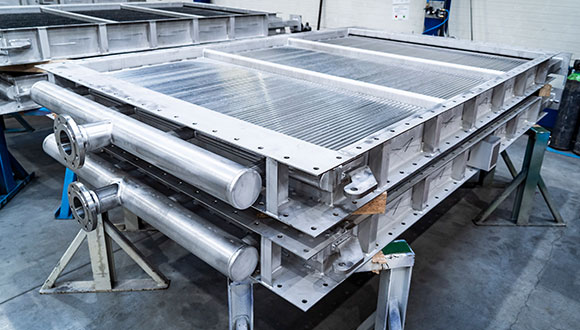

This project contained the design and production of various heat exchangers including inlet and outlet ducting. For this project we have provided in cooperation with NMH:

Steam and condensate are used here to de-ice and preheat ambient air. Aluminium fins ensure compactness of these heat exchangers and efficient heat transfer processes. These PED Cat IV heat exchangers are designed for design conditions of 18 barg and 220 °Celsius.

The various heat exchangers will be installed in Belgium and used for heat recovery in a drying system within the food industry.

With our team of experienced engineers, we offer a total solution concept; from thermal engineering to mechanical engineering, project management, and in-house production. Every single part of your installation will be engineered and produced in-house.

In 2015, Geurts became part of the Heilig Group. This extension offers our customers financial stability and broad access to the group-wide knowledge leading to further innovations.