PRODUITS

CONCEPTION DE PRODUITS POUR L’ÉCHANGE DE CHALEUR ET LA RÉCUPÉRATION DE LA CHALEUR PERDUE

Là où nombre d’industries avaient l’habitude de ressentir la pression liée à l’efficience opérative et économique, la réduction de l’empreinte carbone est aujourd’hui un facteur supplémentaire qui ne peut plus être ignoré. Ceci demande une conception innovante des procédés de production, des installations et des équipements dans leur intégralité.

SOLUTIONS SUR MESURE

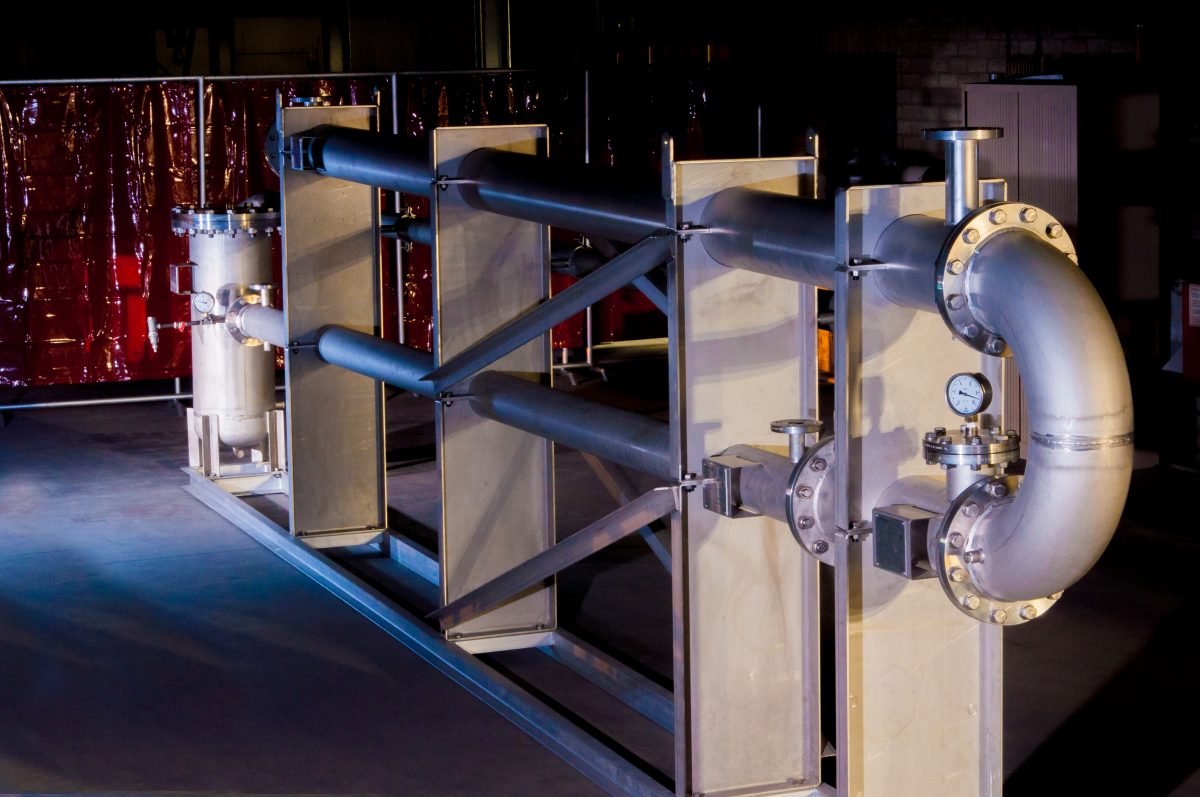

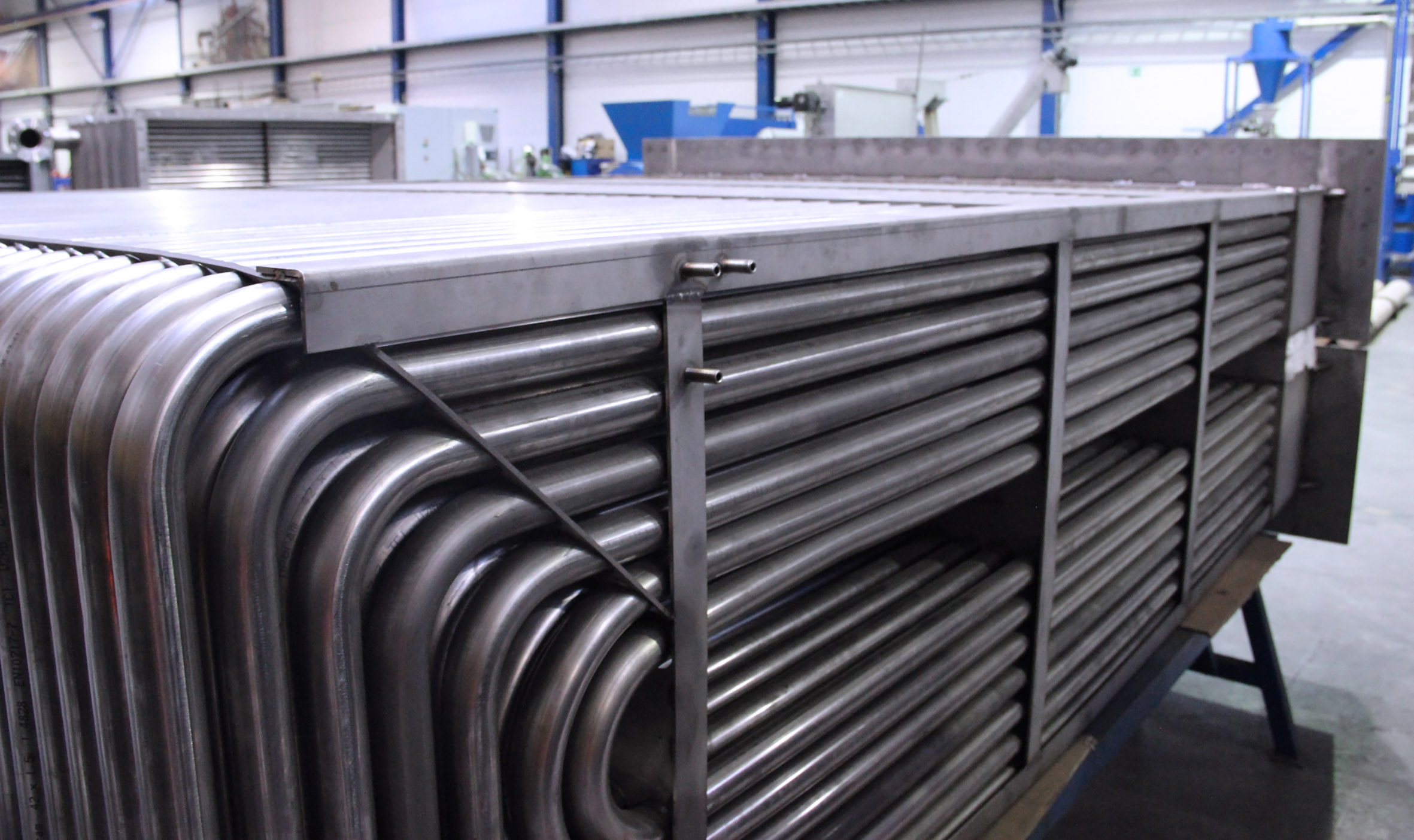

Geurts fournit toute une gamme d’échangeurs de chaleur et de produits de récupération de la chaleur perdue pour régénérer de la chaleur et recycler l’énergie en énergie renouvelable à partir de différents procédés de production. Nos ingénieurs expérimentés conçoivent des solutions sur mesure comprenant un équipement pour haute pression (PED), pour températures de fluides extrêmement élevées (liquides et gaz) ou pour des substances dangereuses qui demandent des applications complexes et spécialisées.

À partir de notre site de production sur site, nous proposons une solution complète; des calculs liés au transfert de chaleur et conception jusqu’à la production de votre préchauffage d’air ou de votre échangeur de chaleur spécifique. Un contact unique pour une solution globale.

Anglais

Anglais Néerlandais

Néerlandais Allemand

Allemand